High voltage cables can be super flexible

Posted on

High voltage wire applications can be found in every industry. High voltage wire and cable doesn’t have to be bulky and stiff. High voltage lead wire and cables can be manufactured to be extremely flexible wire and cable while meeting high voltage requirements by using high strand conductors and flexible wire insulation and jacket materials. Co-extruded silicone cables also offer low corona, high flexibility while maintaining high voltage properties.

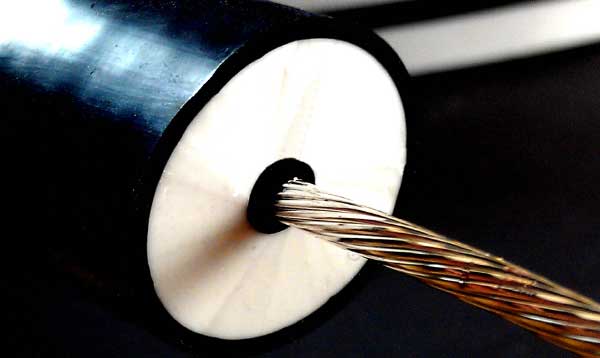

There are several factors which makes a wire or cable high voltage such as, conductor diameter, insulation material and insulation wall thickness. Corona discharge can damage the wire insulation and must be considered in the design. Ways to reduce damage caused by corona discharge is by reducing the air gaps between insulation and conductor. This is accomplished by adding a semi-conductive “sheath” around the conductor which increases the conductor diameter and reduces the gap between conductor and insulation. C0-extrusion of silicone is a process where the semi-conductive layer is extruded at the same time as the insulating material (pictured) enabling the high voltage wire to be extremely flexible and low corona.

For thinner options for high voltage corona resistant hook up and lead wires can be made with FEP, TFE, and PTFE. Though Silicone hook up wire has excellent dielectric properties and is used in many high voltage applications, it does have a thicker wall thickness than FEP,TFE, or PTFE. For applications requiring an extremely flexible high voltage wire to be UL certified wire or MIL-SPEC wire, specify UL3239 with silicone or the MIL-W-16878.

High voltage wire and cable can be manufactured in many sizes and configurations for your specific application. You don’t have to settle for off the shelf solutions, custom wire and cable manufacturers take your application and requirements into consideration when designing your cable.

Applications for high voltage wire include:

- MRI machines

- Generators

- Appliances

- Robotics

- Lighting

Every application has it’s unique needs and must be addressed when designing custom cable. A while back we had a customer in the entertainment industry that provides lighting and power to movie sets on location. They needed an extremely flexible high voltage cable that could be easily routed around the movie set while supplying power for the lighting equipment from the generators. The cable needed to be an extremely flexible cable which could withstand abrasion from being dragged on the ground, stepped on and rolled over. Calmont designed a high voltage super flexible cable to meet these requirements using high strand count silicone insulated conductors with a special lay. The outer jacket was made from polyurethane to resist abrasion while being flexible enough to maneuver around the sets. The cables performed excellent and outlasted the previous cables they replaced. Custom cables are manufactured for the type of use they must endure which gives the cables an advantage over off the shelf.

Contact Calmont with your high voltage wire and cable requirement and let us design the perfect cable for your application.